When retro computing is mentioned, printers hardly get any attention.

When retro computing is mentioned, printers hardly get any attention.For some reason not many people seem to have fond memories of such a devices or are willing to share them. And lets be honest, the early printers were generally DOT-matrix printers and were in many cases pretty large, heavy, expensive, noisy, low print quality and sometimes even required the use of special perforated paper. A thing only important if you managed to find the correct printer driver to make your printer perform all the tricks the adds promised. But perhaps people don't talk about printers because these machines just did what the needed to do.

Anyway, when you mention retro computer printers, people stop listening. Yet there were very interesting printers back in the days. For instance, the Brother HR-5 printer and considering the fact that it's a very simple and low maintenance printer, it might just be the perfect little printer for most of your retro computing needs.

What makes this printer so special?

This is an interesting little printer that came in a few variations. Because in those times, computers differed quite a lot and electrical connections came in various standards, a thing very common for that era as the technology was only just reaching the consumer market. Another reason for various models is in the supported character-set, since ASCII wasn't widely accepted by home computers and although most computers had lot's of things common with ASCII, they also had some special graphical symbols that weren't in the ASCII character-set at all.

Below you can see the 3 different models of this type of printer which aimed on 3 different markets. The HR-5 (PC), HR-5X (MSX), HR-5C (COMMODORE)

As you can see, it's looks quite a bit different compared to other printers of that era. The HR-5 series wasn't heavy, it wasn't loud, it was affordable (especially if you were willing to wait for a discount offer), it could print on normal paper and thermal paper, it even was able to operate on batteries and small enough to be carried in a briefcase, but who would want that?

As you can see, it's looks quite a bit different compared to other printers of that era. The HR-5 series wasn't heavy, it wasn't loud, it was affordable (especially if you were willing to wait for a discount offer), it could print on normal paper and thermal paper, it even was able to operate on batteries and small enough to be carried in a briefcase, but who would want that?

Well, it's a thermal printer. Meaning that it prints using heat. The print-head is not an array of little hammers (like an ordinary dot-matrix impact printer), nope, the print-head of a thermal printer consists of tiny heating elements. These are pressed against the special paper or thermal transfer ribbon and when the are hot the paper changes color. Now this doesn't work with ordinary paper (unless you use the special thermal transfer ribbon) you need thermal paper. Which is something quite ordinary these days. Almost every receipt you get from the supermarkets cash register is printed using this principle. Thermal paper always feels a bit thin, smooth or slick.

The reason why thermal printer are so widely used these days, is simply because they are very low maintenance and have very few moving parts. A modern thermal printer has a print-head that is spread completely across the entire width of the paper (so for 300 pixels wide, it would have 300 tiny heater elements). But the Brother HR-5 is more of a hybrid, it has only 9 heating elements and these are moved in the same way as an ordinary dot-matrix impact printer. So there is still a mechanism for moving the print-head. But that was mostly done to save cost. In fax machines ...................................

What is thermal printing?

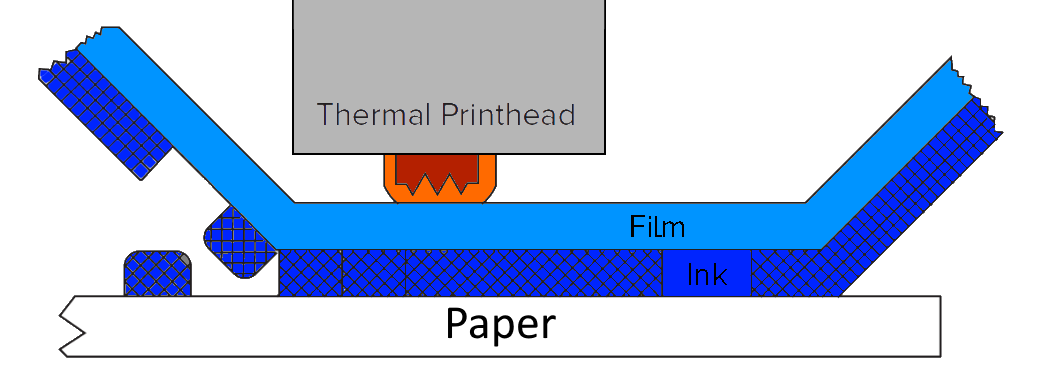

Now, after reading the phrase "thermal printing" some question marks might arise with some people, so what is a thermal printer and how does it work?

In essence it is very simple a "thermal printer" print using heat where an impact printer uses little hammers to make the dots of the DOT-matrix patterns the printer can print. Thermal printing exist primarily in two types: "thermal transfer printing" and "direct thermal printing". And the amazing things is that the Brother HR-5 printers support both types.

Thermal transfer printers

Thermal transfer printers work by using a print-head that applies heat to a ribbon that has a wax or resin coating, depending on the type of media. The heat from the print-head melts the wax or resin and transfers it from the ribbon onto the media. This is why this process is called thermal transfer, the "ink" in transferred from the ribbon to the paper where it is absorbed and remains permanently. This technique provides image quality and durability. Thermal transfer printers can accept any kind of paper or other flexible media at the cost of an additional "thermal ink ribbon" making printing high quality, but relatively expensive.

The brother HR-5 can use special transfer ribbon cartridges (see the image below). When the cartridge is removed and unspooled, you can see very clearly everything that has been printed. In other words, if you are writing top-secret stuff... do not use this technology, because you are leaving a perfect copy for everyone to read. But it also demonstrates why you can use such a ribbon only once. And as you can see, the usage of the ribbon by this printer isn't very efficient either, you might call it pretty wasteful. Because in between characters and spaces the ribbon does not need to be used, yet it is discarded as if it was used anyway. For understandable reasons of design simplicity, but still.

The brother HR-5 can use special transfer ribbon cartridges (see the image below). When the cartridge is removed and unspooled, you can see very clearly everything that has been printed. In other words, if you are writing top-secret stuff... do not use this technology, because you are leaving a perfect copy for everyone to read. But it also demonstrates why you can use such a ribbon only once. And as you can see, the usage of the ribbon by this printer isn't very efficient either, you might call it pretty wasteful. Because in between characters and spaces the ribbon does not need to be used, yet it is discarded as if it was used anyway. For understandable reasons of design simplicity, but still.

Direct Thermal Printing

Direct thermal printers work by creating images directly on the printed material without using a ribbon, toner or ink. Instead, this method uses chemically treated, heat-sensitive media also referred to as "thermal paper". This paper greatly darkens when exposed to heat, which happens selectively under control of the thermal print-head. As a result, this media is more sensitive to light, heat and abrasion. Meaning that labels and tags are not as long lasting. Images can fade over time, and media will darken if overexposed to heat, light or other catalysts. The main advantage of this type of printing is a very low maintenance type of printing, the only thing that the printer requires is the paper it needs to print on and nothing more, making printing relatively cheap and the printer itself very easy to use. For this reason this type of printing is very common for printing of receipts. Now the Brother HR-5 is an A4 capable printer, so use fax rolls of 210mm wide. But with some simple modifications the printer could be made to hold the much smaller width cash register rolls too. Although that paper would be a bit too narrow for anything practical, it could be fun to experiment with.

Specifications of the HR-5 series

print-head: 9-pin thermal DOT-matrix

Dot pitch: 1/80 inch

Character types: PETSCII, ASCII

Character config: 8 pixels (height) * 5 pixels (width) (although the bottom pixel, the 8th pixel is always off, so basically the character set is 7*5 pixels)

Print range: 80 chars per line (normal width), 40 chars per line (double width)

Print range: 480 pixels per line (graphical mode)

Print direction: bi-direction for text mode, uni-directional for graphic-mode

Print speed: 30 characters per second

Buffer memory: 1 line (80 bytes)

Line space: 1/6 inch, 1/9 inch (selectable via dip switch when printing text) OR 14/144 inch when printing in graphical mode

Paper: A4 (8,3inch or 210,8mm wide) or Letter (8,5 inch or 216,0mm wide)

Paper roll: max. outer diameter 2,76 inch or 70mm, min. inner diameter 0,47 inch or 12mm

Ribbon cartridge: 1/4 inch or 6,35mm black, thermal (one time use only) disposable cartridge

Interface: Centronics, RS232C, CBM serial (HR-5C)

Operating temperature: 10C..40C

Storage temperature: -20C..55C

Humidity:20%..80% (during usage) non condensing

Power req.: Battery (4x UM-1) OR a 6V/2A adapter

Power usage: 6.0 Watt

Size: 11,9x6,8x2,6 inch or 303x174x65mm

Weight: 1,6kg (without batteries)

note: The HR-5C seems to be compatible with the Commodore MPS803

How it all started:

My fond memories of this little printer have actually nothing to do with printing itself. A long long time ago when I was a kid, I purchased this printer on a flea market for only 5 guilders. A ridiculous low price to pay for a printer in those days. So there had to be a catch... but I was very young and naive so I grabbed the hard earned pocket money and gave it to the seller.

At home I discovered that the little printer required special paper or a special ribbon, both of which were to be considered unobtainable in my universe. Mostly because I didn't know where to look or who to ask. So the printer never printed a single (visible) line.

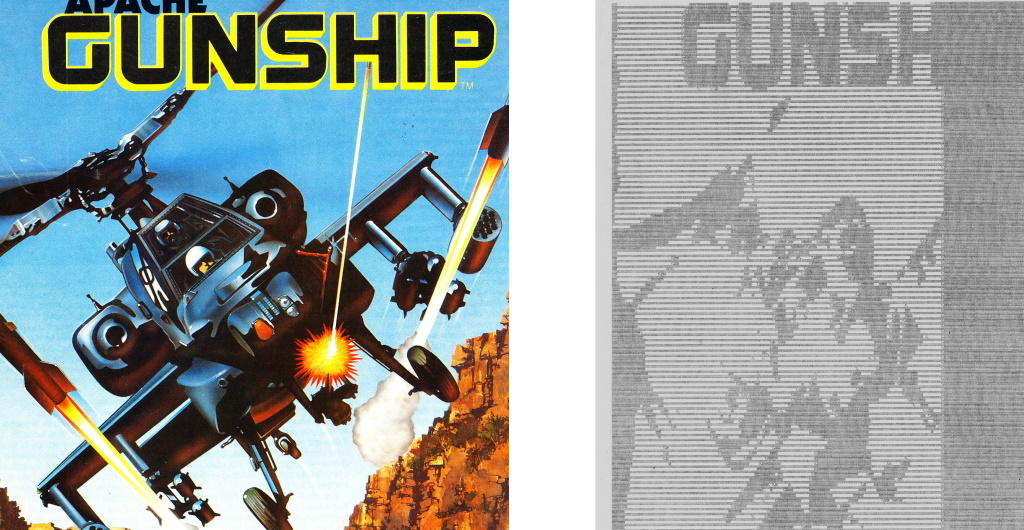

However, the mechanism was fun to play with as I could still control it with my C64 using ordinary printer control commands (thankfully the manual was included otherwise I would have been completely clueless regarding those commands). I attached a simple reflective IR-photo sensor and used it to do some experiments with scanning in images. Now this was all play (I was just about the age 14 and clueless) so don't expect anything serious. But it sort of worked and kept me busy. Now I programmed it in BASIC, so no fancy stuff like hires, dithering, grey-scale. I do no longer have that hardware or code, but basically it came down to sending the commands of advancing the print-head a tiny bit to the right and after a few hundred "pixels" advance the paper a tiny bit forward, return the head to the start and start scanning the next line of "pixels". The photosensor was connected directly to the pot-input and everything code related was written in basic. It was slow, very slow. Low res, very low res. Useless, very useless. But it was fun! Below is shown the one and only image I ever kept, by showing it here you can get an idea of the result of these experiments.

Now remember that I was young with limited funds and electronic knowledge and I didn't even knew an IR-sensor doesn't see the same colors as a human eye does. But most of all that a glossy magazine paper is way to reflective by itself. Now, the modern me would have said that I should have used it mainly for simple large felt tip pen drawings. And I'm sure that indeed that would have worked great... but the biggest problem there was that I couldn't draw a simple stick figure if I wanted to and didn't knew any graphical artists that could use a scanner. So eventually the setup was taken apart and its parts were used for years to come in all sorts of other experiments.

Now remember that I was young with limited funds and electronic knowledge and I didn't even knew an IR-sensor doesn't see the same colors as a human eye does. But most of all that a glossy magazine paper is way to reflective by itself. Now, the modern me would have said that I should have used it mainly for simple large felt tip pen drawings. And I'm sure that indeed that would have worked great... but the biggest problem there was that I couldn't draw a simple stick figure if I wanted to and didn't knew any graphical artists that could use a scanner. So eventually the setup was taken apart and its parts were used for years to come in all sorts of other experiments.

Downloads:

User manual

Dutch user manual for the Brother HR-5C : Brother_HR-5C - Manual_Dutch_00.pdf

Adverts found in magazines

Dutch advert, Commodore dossier : Advert - Brother_HR-5C.jpg

English advert, Sinclair Projects Issue 1984-08 (page 1) : Advert - Brother_HR-5.png

Reviews found in magazines

64er (1984 issue 10, page 18) : 64er_1984-10 - page18.pdf

64er (1985 issue 5, page 15) : 64er_1985-05 - page15.pdf

Your Spectrum 15 - Thermal Printers.htm : Your Spectrum 15 - Thermal Printers.htm